Case Study

Project objective

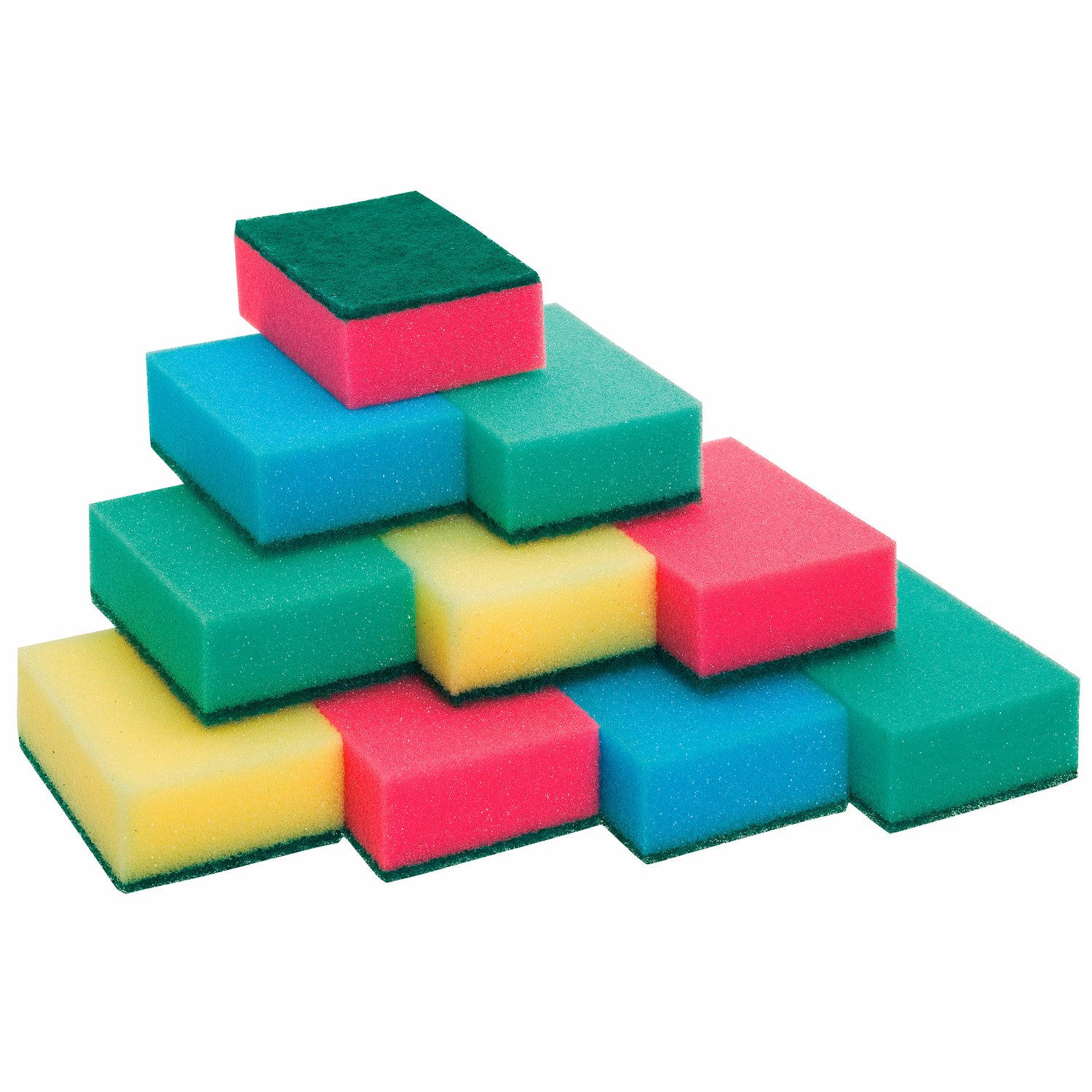

The project consists of developing a supervision and control system for a cleaning material manufacturing plant. The system controls the processes and elements associated with the dosing system of ingredients to obtain mixtures that will be applied to the final product.

The processes that are controlled are:

- Automatic loading by means of recipes.

- Recipe editing.

- Component editing.

- Load status display.

- Automatic load adjustments.

- Control of manual loads.

The control system is based on Rockwell Automation technology:

- The touch operation panel is developed with RSView Studio ME.

- The controller is a ControlLogix and developed using RSLogix 5000.

- Communications software: RSLinx.

- Controlnet Configuration: RSNetworks for Controlnet.

- ControlLogix-Panel communications: They are carried out via Ethernet.